Commercial/Furniture Plywood

Throughout the production process, strict quality control measures are implemented to ensure that the plywood meets the necessary standards and delivers reliable performance in construction applications.

01. Veneer Grading

After being coated with water – resistant glue, veneer will be arranged in layers so that they are perpendicular to the direction of the wood grain of each layer.

Placing boards along the grain of the wood helps to increase elasticity and high shear strength.

02. Veneer Tapering (*)

Feather or taper the edges of veneer sheets to prevent overlapping when laid up. Ensures smoother surface and avoids bumps in finished panel.

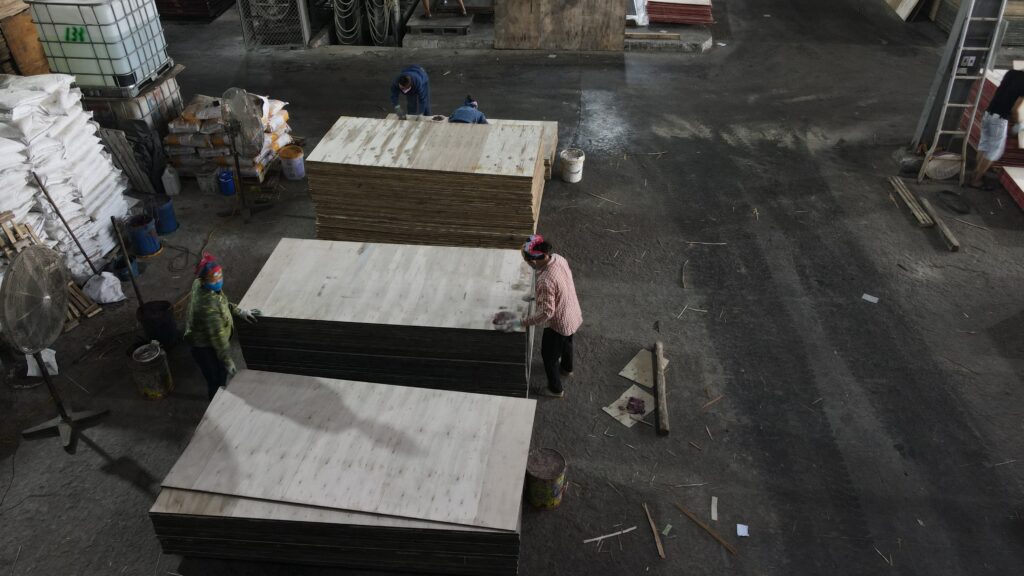

03. Veneer Lay-Up

After being coated with water – resistant glue, veneer will be arranged in layers so that they are perpendicular to the direction of the wood grain of each layer.

Placing boards along the grain of the wood helps to increase elasticity and high shear strength.

04. Cold Pressing

The core board is taken for cold pressing to shape the structure of the plywood. It helps hold the veneers firmly in place before hot pressing, ensuring better alignment and bonding strength.

This step improves product quality and reduces defects like delamination or surface unevenness.

05. Hot Pressing – 1st

Initial thermal bonding stage in plywood production, where glued veneer layers are pressed under high heat and pressure. activates and cures the adhesive, forming a solid core structure. It ensures the veneers are firmly bonded and the panel gains its essential strength. Proper settings during this stage are crucial for minimizing warping and achieving consistent quality.

06. Pre Trimming

Roughly trim the edges of pressed boards to remove uneven sides. Ensuring better effectiveness in following steps like sanding and veneer lamination

07. Light Sanding (*)

Light sanding is performed on the core board to remove surface dust, fiber, and uneven spots. This ensures better adhesive bonding and improves surface uniformity for the next pressing stage.

08. Initial Surface Treatment (*)

Initial surface sanding prepares the panel for face veneer lamination

09. Laminate Face Veneer (*)

Apply glue and attach high-grade face veneers (Acacia or Eucalyptus) with grains aligned parallel to the long edge. Ensure bubble-free application.

10. Hot Pressing – 2nd (*)

Press the face veneer onto the plywood core using heat and pressure to achieve strong bonding and smooth surface integration.

11. Surface Treatment - 2nd

Inspect surface after pressing, remove excess glue, and do minor surface leveling if necessary to prepare for decorative lamination.

12. Sanding – 2nd

Full surface sanding of the panel using wide belt sander to achieve uniform thickness and smoothness across the board.

13. Laminate Decorative Veneer (Birch, Okoume, Bintangor, etc.)

Apply glue and lay decorative veneer sheet over the face layer, aligning carefully for visual consistency.

14. Hot Pressing – 3rd

Press the final decorative layer under high temperature to ensure bubble-free, flat adhesion. This layer defines the final appearance.

15. Face Sanding (*)

Final fine sanding to enhance surface smoothness and prepare the panel for finishing or direct use.

16. Cut to size & Edge Treatment

Trim the panel to standard dimensions (e.g., 1220×2440mm). Smooth edges, seal gaps, and apply edge treatment for durability and clean appearance.

17. Inspection

The plywood sheets will undergo the inspection of appearance, thickness, size, edge, moisture content and boiling test without delamination

18. Packaging & Shipping

Products are packed according to our own standards or customer requirements, ready for shipment by sea.

get a Quote

For more detailed information, including pricing, customization options, and shipping details, please feel free to contact us.

We are more than happy to assist you with any inquiries or specific requirements you may have. You can reach us through:

Phone/Whatsapp: +84 865 752 906 (Mr. Kris)

Looking forward to hearing from you soon!

Address:

Floor 4, 578 Nguyen Van Cu Street, Long Bien District, Ha Noi City, Vietnam